Our heavy-duty orange and white striped airport windsocks are designed to meet the demanding conditions of Australian aviation and industrial environments. Constructed from high-quality 300D PU polyester fabric, these windsocks are rigorously tested in both real-world and lab conditions, ensuring they meet CASA (Civil Aviation Safety Authority) compliance standards for safety and visibility.

Widely used for aviation, airport, and industrial purposes across Australia, our fluorescent orange and white striped windsocks meet CASA’s stringent standards for visibility and durability. Known for their exceptional colourfastness (resistance to fading from UV exposure) and tensile strength, these windsocks are waterproof, highly visible, and built to last in even the harshest conditions, ensuring superior performance compared to other options on the market.

Our orange and white striped windsocks are built to withstand Australia’s harsh climate. The body is crafted from durable 300D PU polyester, with the inlet mouth reinforced by two layers of the same high-strength material, a webbing layer, and a stiffening band to protect against high-velocity wind gusts. This thoughtful design ensures that your windsock remains effective and durable, regardless of extreme weather conditions.

Our 300D PU polyester material is independently tested to provide outstanding tensile strength, with results of 1218 Warp (N) and 1221 Weft (N). This ensures our windsocks are made from high-strength fabric that can endure the demands of daily use in Australia’s diverse environments. From the dusty outback to coastal regions exposed to salt and wind, our windsocks are built to last.

The lightweight design of our orange and white striped windsocks is crucial for detecting even the slightest wind direction and speed changes. Despite their strength and durability, these windsocks remain highly responsive, flying in even the gentlest breeze, making them ideal for accurate and precise aviation operations.

Ensure your airport, airstrip, or industrial site meets CASA compliance standards while providing the best in safety and performance with our reliable, high-quality windsocks. Designed for durability, visibility, and compliance, these windsocks are the ideal choice for any aviation or industrial application in Australia.

Choose our windsocks for your CASA-compliant windsock solution—built to withstand the elements, ensuring safety and performance for years to come.

So you need a windsock..but now, what size?

Windsock size is often dictated by your viewing distance and how the windsock will be mounted. Of course, if you already have a frame, your windsock diameter will be set and you only need to choose a length that worlds for you. See our Visibility of Windsocks Guide below for more information

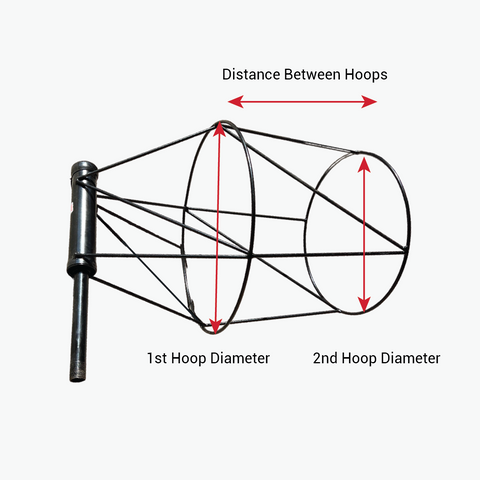

It can get confusing sometimes on how windsocks are measured. The standard is always to measure windsocks diameter and length and present it as: diameter" x length". See the below infographic guide on how to measure a windsock and determine the diameter

If you have a double hoop or extended hoop frame, you should ensure the replacement windsock you purchase will fit over both the outer and inner hoop of the frame. Every frame manufacturer has a different standard and thus some measuring is required to ensure that your replacement windsock will fit onto your frame. Your two options are:

2. If you do have an existing windsock that fits your frame: Measure diameter of the inlet mouth, the length of the windsock as well as the diameter of the outlet mouth. See our guide above on how to measure a windsock.

Step 1) Purchase a Windsock Frame

Step 2) Purchase a stainless steel ¾ NPT female coupling and a ¾ NPT male pole. One size of the coupling will thread into the bottom of the windsock frame and the other will thread onto your pole. The pole you purchase may be long or short, depending on your application and if you are going to attach it to anything else. These can easily be purchased from your local hardware store

Step 3) Attach the pole onto your structure

Step 4) Install the windsock with the use of HD UV rated zip ties (don't buy the white ones, the black ones are usually UV rated.

Note: all frame manufacturers have different specifications. Contact the manufacturer of your frame for instructions on mounting.

Step 1) Purchase a Windsock Frame

Step 2) Purchase a stainless steel ½ NPT female coupling and a ½ NPT male pole. One size of the coupling will thread into the bottom of the windsock frame and the other will thread onto your pole. The pole you purchase may be long or short, depending on your application and if you are going to attach it to anything else. These can easily be purchased from your local hardware store

Step 3) Attach the pole onto your structure

Step 4) Install the windsock with the use of HD UV rated zip ties (don't buy the white ones, the black ones are usually UV rated.

Note: all frame manufacturers have different specifications. Contact the manufacturer of your frame for instructions on mounting.

Note on all Non USA orders: All duties and taxes that may be incurred upon import are the customer's responsibility.

Note: Any of the above shipping timings and costs can be changed at any time at the sole discretion of the Custom Windsock Co.

At the Custom Windsock Company, we want you to be satisfied when you receive your products. All custom products are tailor made to your specifications but because all the finishing and sewing is either done by hand or by a person with a sewing machine, sometimes there is potential for human error, however minimal. Under normal circumstances, our quality control department would pick up on it but sometimes things slip through and the order is dispatched. You might be wondering, what do I do incase of a manufacturing defect?

If our products are faulty in any way, you can return them within 14 days of receipt. You can contact our customer service department by calling 1-833-786-1035 or emailing info@custom-windsocks.com. Let us know your name, order number and concern and we will respond quickly to resolve your issues. We ask you provide a digital image of the fault in your product as well as a clear description of the problem.

In most cases, we will be able to resolve your issue via email. If the fault cannot be verified, you may need to return your product to us for inspection.

With regards to ALL stock products and ALL hardware

All returns must be approved prior to attempting a return. Please email us at info@custom-windsocks.com and state the reason for return to obtain approval for a return. If a return is received that did not obtain prior approval will not be refunded.

In regards to all custom printed products

The Custom Windsock Co has invested in testing its' fabric with the current ASTM standards as well as real-world conditions.

The fabric testing standards stated in the FAA Specification for Windcone Assemblies (FED-STD-191A) are outdated and obsolete as they were published in 1978. No commercial lab in the US has the ability to test on these standards anymore. The industry testing standards have been replaced by equivalent ASTM standards.

We have tested our fabric on:

ASTM D5035 Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method) - Type 2C

ASTM G154-21 Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Materials

Conclusion

We are confident that, if the FED-STD-191A standards were being tested today by any commercial laboratory, our windsock fabric would meet or exceed the requirements stated in FAA Specification for Windcone Assemblies as they have surpassed the equivalent and current industry standards.

For a detailed review of our testing and compliance with FAA specifications, please see our dedicated page here

Even under the harsh Australian sun, our 300D PU polyurethane polyester prevents premature fading and UV degradation

The use of waterproof fabrics allows for consistent windsock responsiveness, regardless of the weather. Our 300D PU polyester is coated with a water proof coating and conforms to FAA specifications*

Stock windsocks are shipped the next business day across Australia. Shipping is normally 4-5 business days within the Australia, depending on your location.

Designed for responsiveness in low and high wind scenarios. Our Airport Windsocks are created to last years in harsh Australian outback, marine and open-field environments and are often used in remote airstrips and heli-pads

Our friendly and knowledgable support team is here to answer any of questions.

☎️ -

1-833-786-1035

📧 -

info@custom-windsocks.com

Feel free to contact us for a quote on bulk orders by completing the fields and including as much information as possible for us to quote you appropriately. Let us know the address and country to which you want your windsocks shipped as well as an approximate time frame during which you wish to have the windsocks in hand.